Contents

- 1 Introduction to Machine Vision Cameras

- 2 Understanding Machine Vision Requirements

- 3 Key Factors to Consider When Choosing a Machine Vision Camera

- 4 Advanced Features and Considerations

- 5 Practical Steps to Choose the Right Camera

- 6 Case Studies and Real-World Examples

- 7 Future Trends in Machine Vision Cameras

- 8 FAQs

- 8.1 What is the difference between CCD and CMOS sensors?

- 8.2 How does a global shutter differ from a rolling shutter?

- 8.3 Why is lighting important in machine vision?

- 8.4 What factors should be considered when selecting a lens for a machine vision camera?

- 8.5 How do embedded processing capabilities benefit machine vision cameras?

- 9 Conclusion

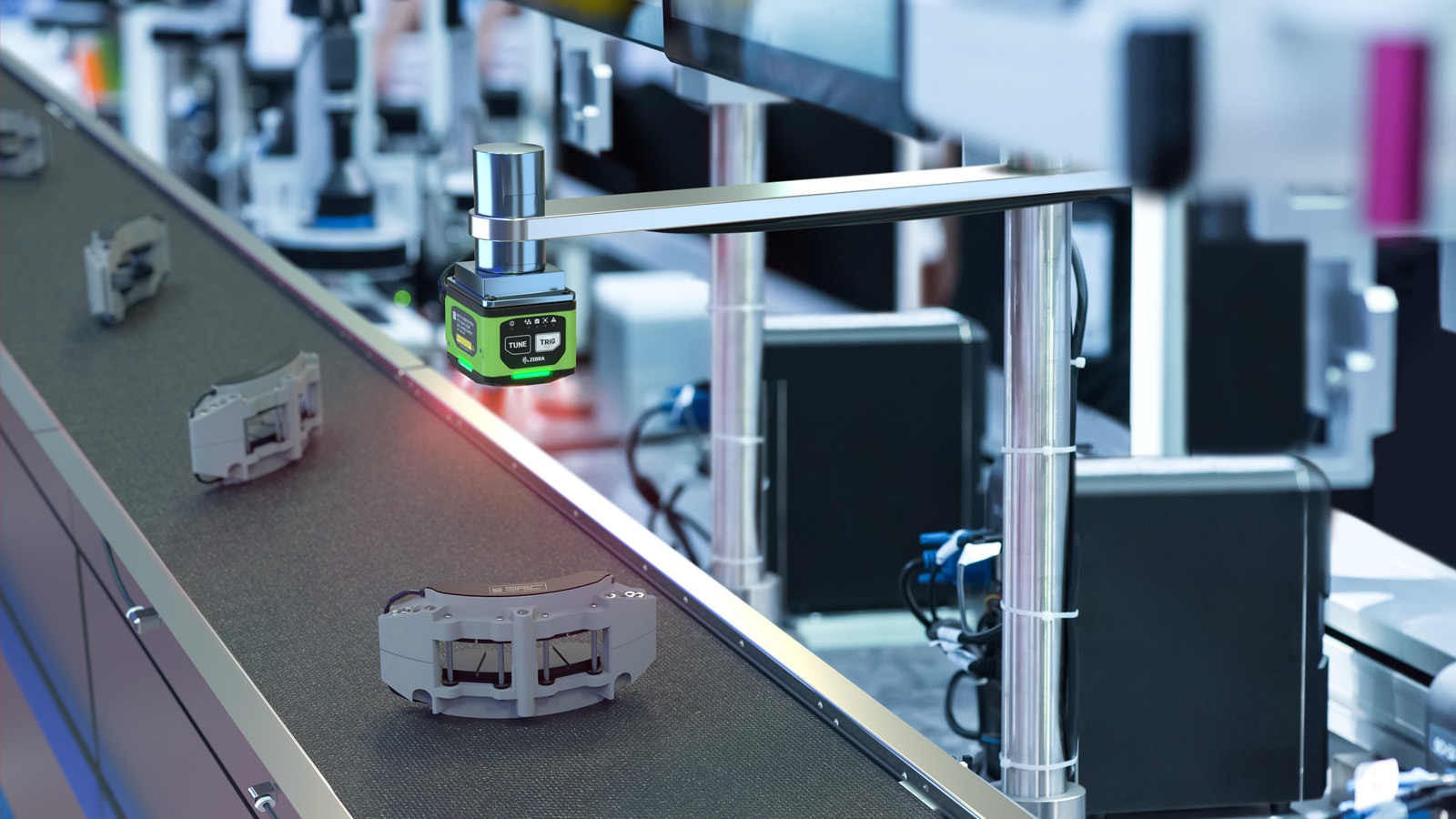

Introduction to Machine Vision Cameras

Machine vision technology is at the forefront of industrial automation, enhancing productivity, accuracy, and efficiency. The choice of a camera is pivotal in determining the success of these systems. Whether you are integrating machine vision into manufacturing, packaging, or quality control, understanding how to choose the right camera is essential.

This article aims to guide you through the complexities of selecting a camera for machine vision, with a special mention of industrial-cameras.com, a leading provider of high-quality machine vision cameras.

Understanding Machine Vision Requirements

Application Specifics

Before selecting a camera, it’s crucial to understand the specific requirements of your application. Different applications demand varying levels of resolution, frame rates, and environmental robustness. Here are some common application areas:

- Quality Inspection: Requires high resolution to detect minor defects.

- Assembly Verification: Needs high speed to keep up with production lines.

- Barcode Reading: Depends on good low-light performance and fast processing.

Environmental Conditions

Consider the environmental conditions where the camera will be used. Factors such as temperature, humidity, and exposure to dust or chemicals can influence the choice of camera. For example, ruggedized cameras with protective housings are essential for harsh industrial environments.

Key Factors to Consider When Choosing a Machine Vision Camera

Resolution

The resolution of a camera determines the level of detail it can capture. Higher-resolution cameras can detect minor defects and provide more detailed images, critical for quality inspection applications. However, higher resolution also means larger data sizes, affecting processing speed and storage requirements.

Frame Rate

The frame rate, measured in frames per second (fps), is crucial for high-speed image capture applications. A higher frame rate ensures the camera can capture fast-moving objects without blur motion. This is particularly important in high-speed manufacturing and assembly lines.

Sensor Type

Machine vision cameras typically use two types of sensors: CCD (Charge-Coupled Device) and CMOS (Complementary Metal-Oxide-Semiconductor). Each has its advantages:

- CCD Sensors: Known for excellent image quality and sensitivity to light. They are ideal for applications requiring high image quality.

- CMOS Sensors: Offer faster frame rates and lower power consumption. They are suitable for high-speed applications and environments where power efficiency is critical.

Shutter Type

The shutter type affects how the image is captured. There are two main types of shutters:

- Global Shutter: Captures the entire image at once, eliminating motion blur. It is essential for high-speed applications.

- Rolling Shutter: Captures the image line by line, which can introduce motion artifacts. It is suitable for slower applications where high frame rates are not required.

Interface

The camera interface determines how it connects to the rest of the machine vision system. Common interfaces include:

- USB: Easy to use and widely supported, but may have limitations in data transfer speed.

- GigE (Gigabit Ethernet): Offers high data transfer rates and long cable lengths, suitable for high-resolution and high-speed applications.

- Camera Link: Provides very high data transfer rates, ideal for demanding applications, but requires specialized hardware.

- CoaXPress: Combines high data transfer rates with long cable lengths, which is suitable for high-performance applications.

Lighting

Proper lighting is crucial for machine vision applications. The choice of lighting can affect the quality and consistency of the images captured. Consider the following types of lighting:

- LED Lighting: Provides consistent and controllable lighting suitable for most applications.

- Infrared Lighting: Useful for applications requiring non-visible light to avoid interference from ambient light.

- Ring Lighting: Provides uniform lighting around the object, ideal for eliminating shadows.

Lens Selection

The lens is vital in determining the field of view and image quality. Consider the following factors when selecting a lens:

- Focal Length: Determines the field of view. Shorter focal lengths provide a wider field of view, while longer ones offer more magnification.

- Aperture: Controls the amount of light entering the camera. A larger aperture (lower f-number) allows more light, useful for low-light conditions.

- Distortion: Lenses with low distortion are essential for applications requiring precise measurements.

Software Compatibility

Ensure that the camera is compatible with your machine vision software. Compatibility with popular machine vision software platforms can simplify integration and provide access to advanced image processing algorithms.

Budget

Budget constraints can significantly influence the choice of camera. While high-end cameras offer superior performance, there are cost-effective options that provide adequate performance for less demanding applications. It’s essential to balance performance requirements with budget limitations.

Advanced Features and Considerations

High Dynamic Range (HDR)

HDR cameras can capture images with a broader range of light intensities, which is helpful in environments with varying lighting conditions. HDR can help capture details in both bright and dark areas of an image, improving the accuracy of machine vision applications.

Multispectral Imaging

Multispectral cameras capture images at different wavelengths of light, including beyond the visible spectrum. This technology is helpful for applications such as material sorting, where other materials reflect light differently at various wavelengths.

3D Imaging

3D cameras can capture the depth information of objects, providing a three-dimensional representation. This is valuable for applications such as robotic guidance, where precise spatial information is required.

Embedded Processing

Some modern machine vision cameras have embedded processing capabilities, allowing image processing to be performed directly on the camera. This can reduce the central processing unit (CPU) load and improve system performance.

Practical Steps to Choose the Right Camera

Step 1: Define Application Requirements

Clearly define the requirements of your application. Consider the resolution, frame rate, and environmental conditions needed for your use case.

Step 2: Research and Compare Options

Research available camera options that meet your defined requirements. Compare the specifications, features, and prices of different models.

Step 3: Evaluate Image Quality

Evaluate the image quality of shortlisted cameras. Request sample images or videos from manufacturers to assess the performance in real-world conditions.

Step 4: Consider Integration and Compatibility

Ensure the chosen camera is compatible with your existing hardware and software systems. Check for available drivers and support from the manufacturer.

Step 5: Factor in the Total Cost of Ownership

Consider the total cost of ownership, including the initial purchase price, maintenance, and any additional equipment needed (e.g., lenses, lighting, cables).

Step 6: Test and Validate

Conduct a trial run with the selected camera in your actual working environment. This will help validate its performance and identify potential issues before full-scale deployment.

Case Studies and Real-World Examples

Case Study 1: Quality Inspection in Electronics Manufacturing

An electronics manufacturer needed a high-resolution camera to inspect solder joints on printed circuit boards (PCBs). They selected a CCD camera with a resolution of 12 megapixels and a global shutter. The camera’s high image quality and precise defect detection capabilities significantly improved the production yield and reduced the rate of faulty products.

Case Study 2: High-Speed Assembly Line Monitoring

A packaging company required a camera to monitor high-speed assembly lines. They chose a CMOS camera with a frame rate of 120 fps and a GigE interface. The camera’s fast image capture and reliable data transfer ensured accurate monitoring and minimized production downtime.

Case Study 3: Barcode Reading in Warehouse Automation

A logistics company implemented machine vision cameras for barcode reading in their automated warehouse. They used cameras with infrared lighting and embedded processing capabilities. This setup allowed for reliable barcode reading even in low-light conditions and reduced the processing load on the central system.

Future Trends in Machine Vision Cameras

Artificial Intelligence (AI) Integration

The integration of AI with machine vision cameras is a growing trend. AI algorithms can enhance image processing capabilities, enabling more accurate and efficient analysis. AI-powered cameras can learn and adapt to different conditions, improving performance over time.

Edge Computing

Edge computing involves processing data close to the source, reducing latency and bandwidth usage. Machine vision cameras with edge computing capabilities can perform real-time analysis and decision-making, which is critical for time-sensitive applications.

Increased Resolution and Speed

Advancements in sensor technology continue to drive improvements in camera resolution and speed. Future cameras will offer even higher resolutions and faster frame rates, enabling more detailed and rapid image capture.

Enhanced Connectivity

New connectivity options, such as 5G, will provide faster and more reliable data transfer for machine vision systems. This will enable real-time remote monitoring and control, expanding the possibilities for industrial automation.

FAQs

What is the difference between CCD and CMOS sensors?

CCD sensors offer better image quality and sensitivity to light, making them ideal for applications requiring high image quality. CMOS sensors provide faster frame rates and lower power consumption, making them suitable for high-speed applications.

How does a global shutter differ from a rolling shutter?

A global shutter captures the entire image simultaneously, eliminating motion blur and making it suitable for high-speed applications. A rolling shutter captures the image line by line, which can introduce motion artifacts but is ideal for slower applications.

Why is lighting important in machine vision?

Proper lighting ensures consistent and high-quality images, critical for accurate image analysis. Different lighting types, such as LED, infrared, and ring lighting, achieve the desired image quality in various applications.

What factors should be considered when selecting a lens for a machine vision camera?

Consider the focal length, aperture, and distortion of the lens. The focal length determines the field of view, the aperture controls the light entering the camera, and low distortion is essential for precise measurements.

How do embedded processing capabilities benefit machine vision cameras?

Embedded processing allows image processing to be performed directly on the camera, reducing the central processing unit (CPU) load and improving system performance. This is particularly useful for applications requiring real-time analysis and decision-making.

Conclusion

Choosing the right camera for machine vision involves carefully considering various factors, including resolution, frame rate, sensor type, shutter type, interface, lighting, lens selection, and software compatibility. By understanding the specific requirements of your application and evaluating available options, you can select a camera that meets your needs and enhances the performance of your machine vision system. For more detailed information and a wide range of machine vision cameras, visit industrial-cameras.com.